The following tables show standard dimensions for keys and their grooves.

Search in blog

Blog categories

Latest posts

Motor Direction

Clearance hole chart for inch bolts and screws according to ASME B18.2.8

One of the earliest forms of comparison. The pigment/binder ratio is the weight ratio of the sum of the pigments...

Popular posts

Featured posts

Blog tags

Photo gallery

No featured images

Archived posts

Top authors

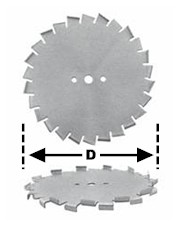

Dispersion Blade Diameter

The blade diameter should be roughly 1/3rd the diameter of the vessel...

Ask any disperser supplier, most operators, the answer is the same. The blade diameter should be roughly 1/3rd the diameter of the vessel.

The truth is, blade diameter should be roughly 1/3rd the diameter of the vessel for a reasonably good dispersion in many dispersion operations . Many, NOT All. The problem is every product is different. Viscosity, rheology, pigment, properties, etc. all play important roles in dispersion. These properties are not as easily modified as is blade diameter.

Case in point, product viscosity and/or rheology results in excessive flow. The product over vortexes, cavitates, or splashes from the tank. Current tip speed is required for adequate shear. One option is to switch to a smaller diameter blade. Running this blade at similar same tip speed (higher rpm) may still deliver the required shear while reducing the voretex depth.

At the other end of the spectrum, a stagnent area is present around the periphery of the tank. A larger bade may be more efficient at establishing flow at the outer edges of the tank.

Blade Diameter

Blade Diameter

Leave a comment

Related posts

What to consider when moving to an Inverter

What to consider when moving to an Inverter

Dual-Axis Centrifugal Mixer - A Better Mix

Dual-Axis Centrifugal Mixer - A Better Mix

JACKETED TANKS AND THERMAL SHOCK

JACKETED TANKS AND THERMAL SHOCK

Disperser Blade Mounting

Disperser Blade Mounting

DISPERSER CONFIGURATION

DISPERSER CONFIGURATION

Latest comments